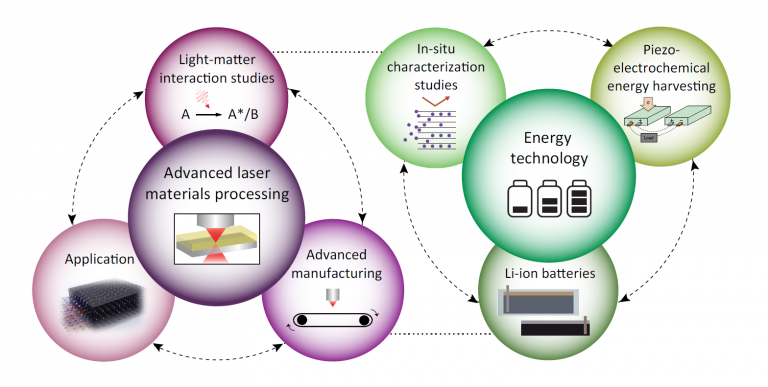

Advanced Laser Materials Processing

Increasing number of novel materials, structures and device are being designed every day to revolutionize our future. Accordingly, new fabrication methods to complement the designs must be developed for actual realization of the devices. In this research area, we are focused on developing new laser-based advanced manufacturing technologies in a reliable, scalable and cost-effective manner and further investigate novel light-based applications.

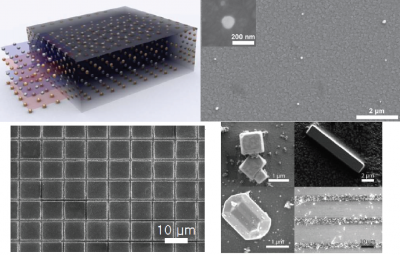

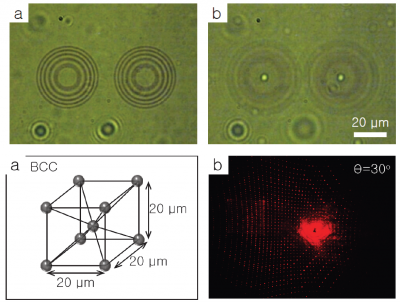

2D/3D high-resolution multi-material direct laser writing

Our direct laser writing technique enables fabrication of 3D metal-dielectric nanocomposite structures of tunable dimensions ranging from hundreds of nanometers to micrometers. This true 3D patterning technique utilizes nonlinear optical interactions between chemical precursors and femtosecond pulses to go beyond the limitations of conventional fabrication techniques that require multiple postprocessing steps and/or are restricted to fabrication in two dimensions. By varying the chemistry multiple materials can be printed to form micro-/nano-crystals and 2D/3D structures.

Applications

Our group investigates various applications of novel laser processing techniques. Our current areas of interests include new graphene based materials, fabrication of optical devices, functional metamaterials and sensors.

Energy Technology

We explore various energy storage materials and perform characterization studies to acquire fundamental understanding of energy storage mechanism. For example, one type of materials of interest is piezoelectrochemical (PEC) materials, a relatively new class of materials, that allows conversion of mechanical energy to electrochemical energy. We aim to understand the fundamental mechanics and materials science behind ion-transport and PEC effects for design optimization of new PEC energy harvesters and next generation batteries.

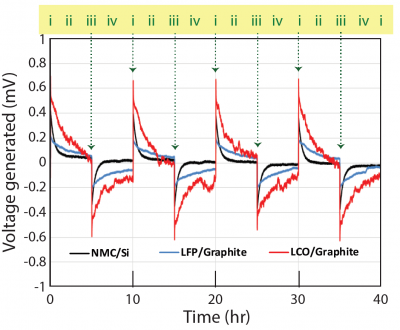

PEC effect / Mechano-electrochemical coupling

Mechanical stress evolution in energy storage materials is a critical issue that arises from swelling of the cells and failure in the design of auxiliary parts that add extra stress to the system. Due to their large swelling properties lithium-ion batteries, for example, is a great candidate for studying the PEC effect (i.e., mechano-electrochemical coupling). Through the PEC effect, these materials can convert ambient mechanical energy into electrochemical energy. Large energy density and relatively slow charge transfer kinetics associated with the PEC process make these systems superior to piezoelectrics for harvesting mechanical energy at low frequencies where every day human locomotion takes place.